Phaj Hlau Stainless

Kev piav qhia txog khoom

| Lub Npe Khoom | Phaj / Ntawv Hlau Tsis Muaj Hlau |

| Tus Qauv | ASTM, JIS, DIN, GB, AISI, DIN, EN |

| Khoom siv | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 321H40, 3 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310L |

| Kev siv tshuab | Txias kos, Kub dov, Txias dov thiab lwm yam. |

| Dav | 6-12 hli lossis Kho Tau |

| Qhov tuab | 1-120 hli lossis Kho Tau |

| Ntev | 1000 - 6000mm lossis Kho Tau |

| Kev Kho Mob Nto | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Keeb kwm | Tuam Tshoj |

| Tus lej HS | 7211190000 |

| Lub Sijhawm Xa Khoom | 7-15 hnub, nyob ntawm qhov xwm txheej thiab ntau npaum li cas |

| Kev Pab Tom Qab Muag Khoom | 24 teev hauv online |

| Peev Xwm Tsim Khoom | 100000 Tons / Xyoo |

| Cov nqe lus | EXW, FOB, CIF, CRF, CNF lossis lwm yam |

| Chaw Nres Tsheb Thauj Khoom | Txhua qhov chaw nres nkoj hauv Suav teb |

| Lub Sijhawm Them Nyiaj | TT, LC, Nyiaj Ntsuab, Paypal, DP, DA, Western Union lossis lwm yam. |

| Daim Ntawv Thov | 1. Kho kom zoo nkauj vaj tse. Xws li phab ntsa sab nraud, phab ntsa ntaub thaiv qhov rais, qab nthab, ntaiv tes, qhov rooj thiab qhov rai, thiab lwm yam. |

| 2. Rooj tog hauv chav ua noj. Xws li qhov cub hauv chav ua noj, dab dej, thiab lwm yam. | |

| 3. Cov khoom siv tshuaj lom neeg. Xws li cov thawv, cov kav dej, thiab lwm yam. | |

| 4. Kev ua zaub mov. Xws li cov thawv ntim zaub mov, cov rooj ua zaub mov, thiab lwm yam. | |

| 5. Kev tsim tsheb. Xws li lub cev tsheb, cov yeeb nkab tso pa tawm, lub tank roj, thiab lwm yam. | |

| 6. Cov khoom siv hluav taws xob. Xws li kev tsim cov plhaub, cov khoom siv qauv, thiab lwm yam rau cov khoom siv hluav taws xob. | |

| 7. Cov khoom siv kho mob. Xws li cov cuab yeej phais, cov cuab yeej phais, cov khoom siv kho mob, thiab lwm yam. | |

| 8. Kev tsim nkoj. Xws li lub cev nkoj, cov kav dej, cov khoom siv txhawb nqa, thiab lwm yam. | |

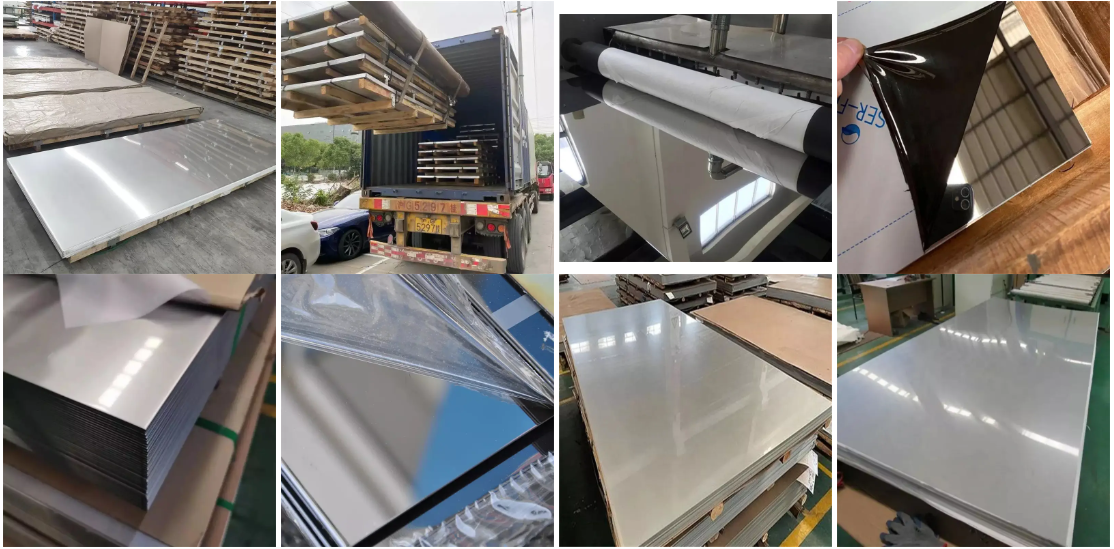

| Ntim Khoom | Pob khoom, PVC hnab, Nylon siv, Cable khi, Txheem export seaworthy pob lossis raws li Kev Thov. |

| Kev Pabcuam Ua Haujlwm | Khoov, Vuam, Decoiling, Xuas Nrig, Txiav thiab lwm yam. |

| Kev kam rau siab | ±1% |

| MOQ | 5 tons |

Lub sijhawm ua thawj coj

| Qhov ntau (tons) | 1 - 50 | 51 - 100 | > 100 |

| Lub sijhawm ua khoom (hnub) | 7 | 15 | Yuav tsum tau sib tham |

Cov Lus Qhia Tshwj Xeeb

| Khoom | Cov Hlau Stainless, Cov Hlau Stainless Phaj |

| Hom Khoom Siv | Ferrite stainless hlau, sib nqus; Austenitic stainless hlau, Tsis yog sib nqus. |

|

Qib | Feem ntau yog 201, 202, 304, 304L, 304H, 316, 316L, 316Ti, 2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 thiab lwm yam |

| 300series: 301,302,303,304,304L, 309,309s, 310,310S, 316,316L, 316Ti, 317L, 321,347 | |

| 200series: 201, 202, 202cu, 204 | |

| 400series: 409,409L, 410,420,430,431,439,440,441,444 | |

| Lwm tus: 2205,2507,2906,330,660,630,631,17-4ph, 17-7ph, S318039 904L, thiab lwm yam | |

| Duplex stainless hlau: S22053, S25073, S22253, S31803, S32205, S32304 | |

| Cov Hlau Stainless Tshwj Xeeb: 904L, 347 / 347H, 317 / 317L, 316Ti, 254Mo | |

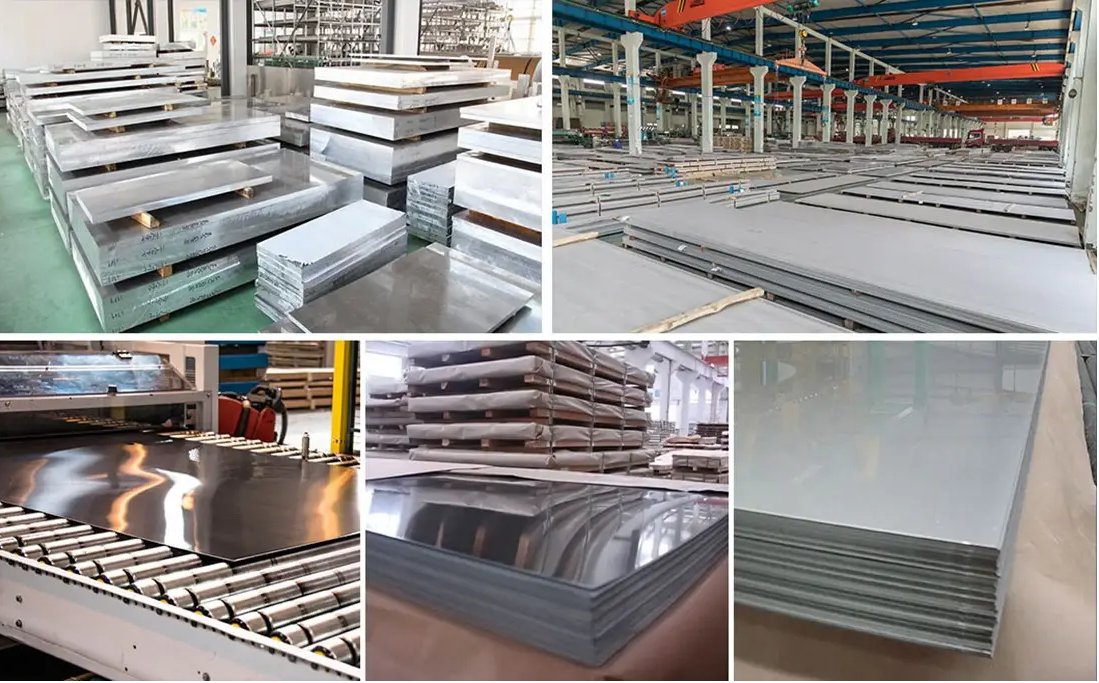

| Qhov zoo | Peb muaj Tshuag, li ntawm 20000 tons. 7-10 hnub xa khoom, tsis pub tshaj 20 hnub rau kev txiav txim ntau |

| Kev Siv Tshuab | Txias Dov / Kub Dov |

| Ntev | 100 ~ 12000 hli / raws li kev thov |

| Dav | 100 ~ 2000 hli / raws li kev thov |

| Qhov tuab | Txias dov: 0.1 ~ 3 hli / raws li kev thov |

|

| Kub dov: 3 ~ 100 hli / raws li kev thov |

|

Nto | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Kev sib npaug: txhim kho qhov tiaj tiaj, tshwj xeeb rau cov khoom uas muaj qhov thov tiaj tiaj siab. | |

| Tawv Nqaij-Pass: txhim kho qhov tiaj tus, ci ntsa iab dua | |

| Lwm Cov Kev Xaiv | Kev Txiav: Laser txiav, pab cov neeg siv khoom txiav qhov loj me uas xav tau |

| Kev Tiv Thaiv | 1. Muaj ntawv sib tham |

| 2. PVC tiv thaiv zaj duab xis muaj | |

| Raws li koj qhov kev thov, txhua qhov loj me tuaj yeem xaiv rau ntau daim ntawv thov. Thov hu rau peb! | |

Kev Kho Mob Nto

| Nto | Kev Txhais Lus | Daim Ntawv Thov |

| TSIS MUAJ. 1 | Qhov chaw tiav los ntawm kev kho cua sov thiab pickling lossis cov txheej txheem sib raug rau tom qab kub dov. | Lub thawv tshuaj lom neeg, yeeb nkab |

| 2B | Cov tiav lawm, tom qab dov txias, los ntawm kev kho cua sov, pickling lossis lwm yam kev kho mob sib npaug thiab thaum kawg los ntawm kev dov txias rau muab qhov ci ntsa iab tsim nyog. | Cov khoom siv kho mob, Kev lag luam zaub mov, Cov khoom siv tsim kho, Cov khoom siv hauv chav ua noj. |

| TSIS MUAJ. 3 | Cov uas ua tiav los ntawm kev txhuam nrog No.100 txog No.120 abrasives teev nyob rau hauv JIS R6001. | Cov khoom siv hauv chav ua noj, Kev tsim kho vaj tse |

| TSIS MUAJ.4 | Cov uas ua tiav los ntawm kev txhuam nrog No.150 txog No.180 abrasives teev nyob rau hauv JIS R6001. | Cov khoom siv hauv chav ua noj, Kev tsim kho vaj tse, Cov khoom siv kho mob. |

| HL | Cov polishing tiav lawm kom muab cov kab polishing txuas ntxiv mus los ntawm kev siv abrasive ntawm cov noob loj tsim nyog | Kev Tsim Kho Tsev. |

| BA (Naj Npawb 6) | Cov uas ua tiav nrog kev kho cua sov ci tom qab dov txias. | Cov khoom siv hauv chav ua noj, Cov khoom siv hluav taws xob, Kev tsim kho tsev. |

| Daim iav (Naj Npawb 8) | Ci ntsa iab zoo li daim iav | Kev tsim kho tsev |

Cov Lus Nug Feem Ntau

Q1: Koj lub sijhawm xa khoom ntev npaum li cas?

A: Feem ntau, peb lub sijhawm xa khoom yog nyob rau hauv 7-45 hnub, yog tias muaj kev thov loj lossis muaj xwm txheej tshwj xeeb, nws yuav raug ncua sijhawm.

Q2: Koj cov khoom muaj cov ntawv pov thawj dab tsi?

A: Peb muaj ISO 9001, SGS, EWC thiab lwm yam ntawv pov thawj.

Q3: Cov chaw nres nkoj xa khoom yog dab tsi?

A: Koj tuaj yeem xaiv lwm qhov chaw nres nkoj raws li koj xav tau.

Q4: Koj puas tuaj yeem xa cov qauv?

A: Tau kawg, peb tuaj yeem xa cov qauv mus rau thoob plaws lub ntiaj teb, peb cov qauv yog pub dawb, tab sis cov neeg siv khoom yuav tsum tau them tus nqi xa khoom.

Q5: Cov ntaub ntawv khoom twg kuv yuav tsum muab?

A: Koj yuav tsum muab qib, dav, tuab thiab lub tuj uas koj xav tau yuav.

Q6: Koj qhov zoo dua yog dab tsi?

A: Kev lag luam ncaj ncees nrog tus nqi sib tw thiab kev pabcuam tshaj lij ntawm cov txheej txheem xa tawm.