Xim siab vuas pobzeb

Cov Lus Qhia Tshwj Xeeb

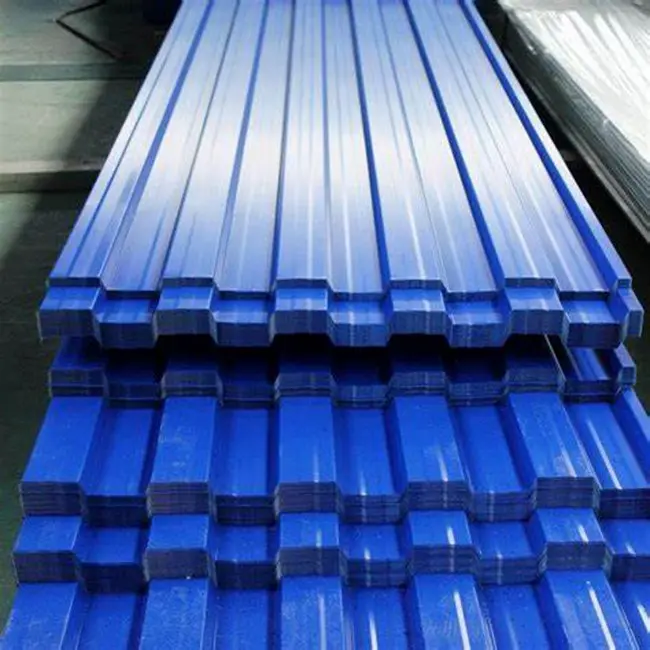

Lub thickness yog 0.2-4 hli, qhov dav yog 600-2000 hli, thiab qhov ntev ntawm lub phaj hlau yog 1200-6000 hli.

Cov txheej txheem tsim khoom

Vim tsis muaj cua sov hauv cov txheej txheem ntau lawm, tsis muaj kev dov kub feem ntau tshwm sim pitting thiab oxide hlau tsis zoo, qhov zoo ntawm qhov chaw, ua tiav siab. Ntxiv mus, qhov tseeb ntawm qhov loj ntawm cov khoom txias-dov yog siab, thiab cov khoom thiab cov qauv ntawm cov khoom txias-dov tuaj yeem ua tau raws li qee qhov kev xav tau tshwj xeeb, xws li cov khoom siv hluav taws xob, cov khoom kos duab tob, thiab lwm yam.

Kev Ua Tau Zoo: feem ntau yog siv cov hlau carbon tsawg, xav tau kev khoov txias thiab kev vuam zoo, nrog rau qee qhov kev ua tau zoo ntawm stamping.

Hom dov txias

(1) Tom qab annealing, nws yog ua tiav rau hauv kev dov txias ib txwm;

(2) Chav tsev Galvanizing nrog cov khoom siv kho ua ntej annealing ua cov txheej txheem galvanizing;

(3) Yeej tsis tas yuav ua tiav lub vaj huam sib luag.

Siv

Kev tsim khoom muaj kev ua tau zoo, uas yog, los ntawm kev dov txias, qhov tuab tuaj yeem nyias dua, qhov tseeb dua ntawm cov hlau txias dov thiab cov hlau phaj, ncaj siab, qhov chaw tiav, qhov chaw huv si, yooj yim rau kev tsim cov txheej txheem plating, ntau yam, daim ntawv thov dav, kev ua haujlwm siab stamping thiab tsis muaj kev txwv tib lub sijhawm, cov yam ntxwv ntawm qhov tso zis qis, yog li kev tsim khoom nrog ntau yam kev siv, Feem ntau siv rau hauv tsheb, luam ntawv hlau thoob, kev tsim kho, cov ntaub ntawv tsim kho, tsheb kauj vab thiab lwm yam lag luam, tab sis kuj yog qhov kev xaiv zoo tshaj plaws ntawm cov txheej txheem txheej txheem hlau organic.

Xim hlau kauj yog ib hom khoom sib xyaw, tseem hu ua xim coated steel phaj yog ua los ntawm cov hlau strip hauv cov kab ntau lawm tom qab kev ntxuav degreasing nto tas mus li, phosphating thiab lwm yam kev kho tshuaj hloov pauv txheej, coated nrog cov organic txheej los ntawm cov khoom ci.

Xim kauj yog ib hom khoom sib xyaw, ob qho tib si hlau phaj thiab cov khoom siv organic. Tsis yog tsuas yog lub zog kho tshuab ntawm hlau phaj thiab kev ua tau yooj yim molding, tab sis kuj yog cov khoom siv zoo nkauj organic, tiv taus corrosion.

Cov hom txheej xim tuaj yeem muab faib ua: polyester (PE), silicon modified polyester (SMP), polyvinylidene fluoride (PVDF), polyester tiv taus huab cua siab (HDP), clinker sol.

GB/T 12754-2006 Xim coated steel phaj thiab strip

GB/T 13448-2006 Xim txheej hlau phaj thiab strip xeem txoj kev

GB 50205-2001 Code rau kev lees txais kev tsim kho zoo ntawm kev tsim kho hlau

Cov ntaub ntawv xim hlau tau muab faib ua tsib pawg: ntim khoom, khoom siv hauv tsev, khoom siv hauv tsev, khoom siv kho qhov muag thiab khoom siv kho kom zoo nkauj. Ntawm lawv, cov khoom siv hauv tsev xim hlau yog qhov zoo tshaj plaws thiab zoo tshaj plaws, qhov yuav tsum tau ua ntau tshaj plaws.

Cov txheej txheem ib txwm muaj ntau pawg, qhov siab tshaj plaws yog fluorocarbon, uas tuaj yeem kav ntev li ntawm 20 xyoo. Feem ntau faib los ntawm cov chaw ua hlau hauv daim ntawv ntawm cov menyuam mus rau ntau qhov chaw. Cov hlau xim phaj peb feem ntau pom hais txog cov hlau ua tiav, qhov tuab yog li 0.2 ~ 10 hli, nws yog tsim los ntawm cov khoom sau nruab nrab thiab cov hlau xim phaj ntawm ob sab. Ntawm lawv, cov xim phaj tuab muaj 0.4 hli, 0.5 hli, 0.6 hli thiab lwm yam tuab sib txawv, txheej nruab nrab tuaj yeem yog polyurethane, pob zeb wool lossis ua npuas yas. Vim tias muaj cov profile tshwj xeeb, yog li lub tsev Hoobkas nrog cov xim hlau phaj tsim kho ceev heev (xws li THE SARS xiaotangshan tsev kho mob), tab sis lub zog qis. Cov khoom siv ntawm cov xim coated hlau phaj yog cov khoom siv txias dov, kub dip galvanized substrate thiab galvanized zinc substrate. Cov hom txheej tuaj yeem faib ua polyester, silicone hloov polyester, polyvinylidene fluoride thiab plastisol. Lub xeev nto ntawm cov xim coated hlau phaj tuaj yeem faib ua coated phaj, embossed phaj thiab luam ntawv phaj.

Cov hlau phaj xim coated yog siv dav hauv cov khoom siv hauv kev tsim kho thiab kev lag luam thauj mus los, rau kev lag luam kev tsim kho feem ntau yog siv rau cov qauv hlau cog, tshav dav hlau, tsev rau khoom thiab tub yees thiab lwm yam kev lag luam thiab kev lag luam ru tsev phab ntsa thiab qhov rooj, cov tsev pej xeem nrog cov hlau phaj tsawg dua.

Lwm yam kev siv hauv kev lag luam xws li cov khoom siv rau tsheb kauj vab, ntau yam kav dej vuam, txee hluav taws xob, txoj kev loj, txee khw muag khoom loj, txee rau khoom hauv tsev rau khoom, laj kab, lub hau dej kub, ua thoob, ntaiv hlau thiab cov khoom siv stamping ntawm ntau yam duab. Nrog rau kev txhim kho tas mus li ntawm kev lag luam, kev ua tiav xoom thoob plaws hauv kev lag luam, kev txhim kho sai ntawm cov chaw ua khoom loj hlob sai, qhov kev thov rau phaj tau nce ntxiv heev, tab sis kuj ua rau muaj kev thov rau phaj pickling kub dov.

Khoom Zaub